About

Aerospace

Matrix supports aerospace manufacturers and suppliers by integrating robotic automation that improves repeatability, guarantees consistent quality, and increases throughput for precision machined components and subassemblies. We focus on robotic machine tending, robotic metal finishing, end of line automation, and inspection / traceability solutions designed for aerospace with rigid expectations around process control, part protection, and documentation.

Who We serve

We work with aerospace teams that need reliable automation that integrates cleanly with existing machining and quality systems while reducing ergonomic exposure and product launch risks, including:

- Aerospace manufacturers and suppliers producing precision-machined metal components and castings

- Teams seeking to standardize finishing quality, reduce ergonomic risk, and de-risk integration with existing machining, finishing, and pack-out processes

- Operations that require traceability and inspection data capture to support customer and regulatory expectations

Parts We Work With

Aerospace programs frequently demand consistent handling, controlled finishing, and documented process steps across repeatable part families. Typical components include:

- Precision-machined aerospace components made of aluminum, steel, and iron

- Cast and machined subcomponents and casings

- Brackets, mounts, housings, and similar part families where consistent edge condition and surface finish is critical

Applications

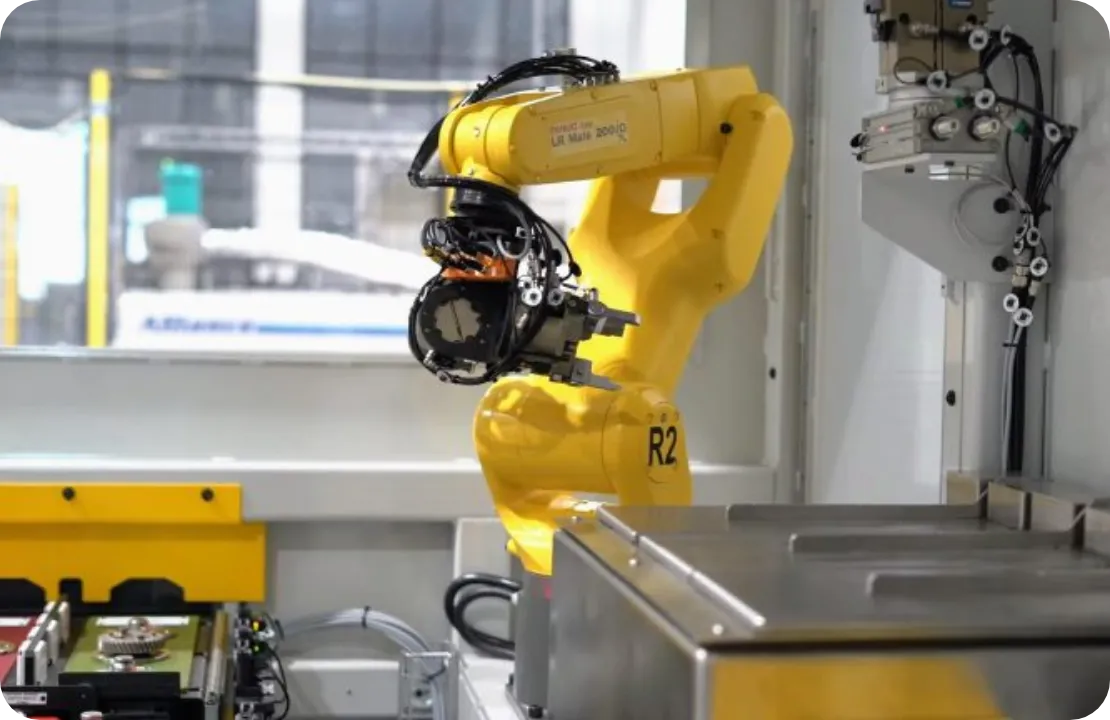

Robotic Machine Tending

Matrix engineers industrial and collaborative tending cells that load and unload CNC machines, grinders, and related equipment across a wide range of aerospace part families. Our approach emphasizes stable machine utilization, consistent handling, and dependable integration with plant-floor systems. Key features include:

- Flexible cell designs for CNCs and other machine tools, tailored to part geometry and cycle time requirements

- Quick-change grippers and modular end-of-arm tooling to support multiple part types and future program changes

- Part presentation options using drawers, trays, conveyors, or bins to match space constraints and safe operator interaction

- Optional in-cell gauging and measurement to verify critical features and reduce downstream inspection burden

- Offset feedback to machines to compensate for tool wear and maintain part quality over long production runs

- MES and ERP integration to log process steps and enable traceability when required

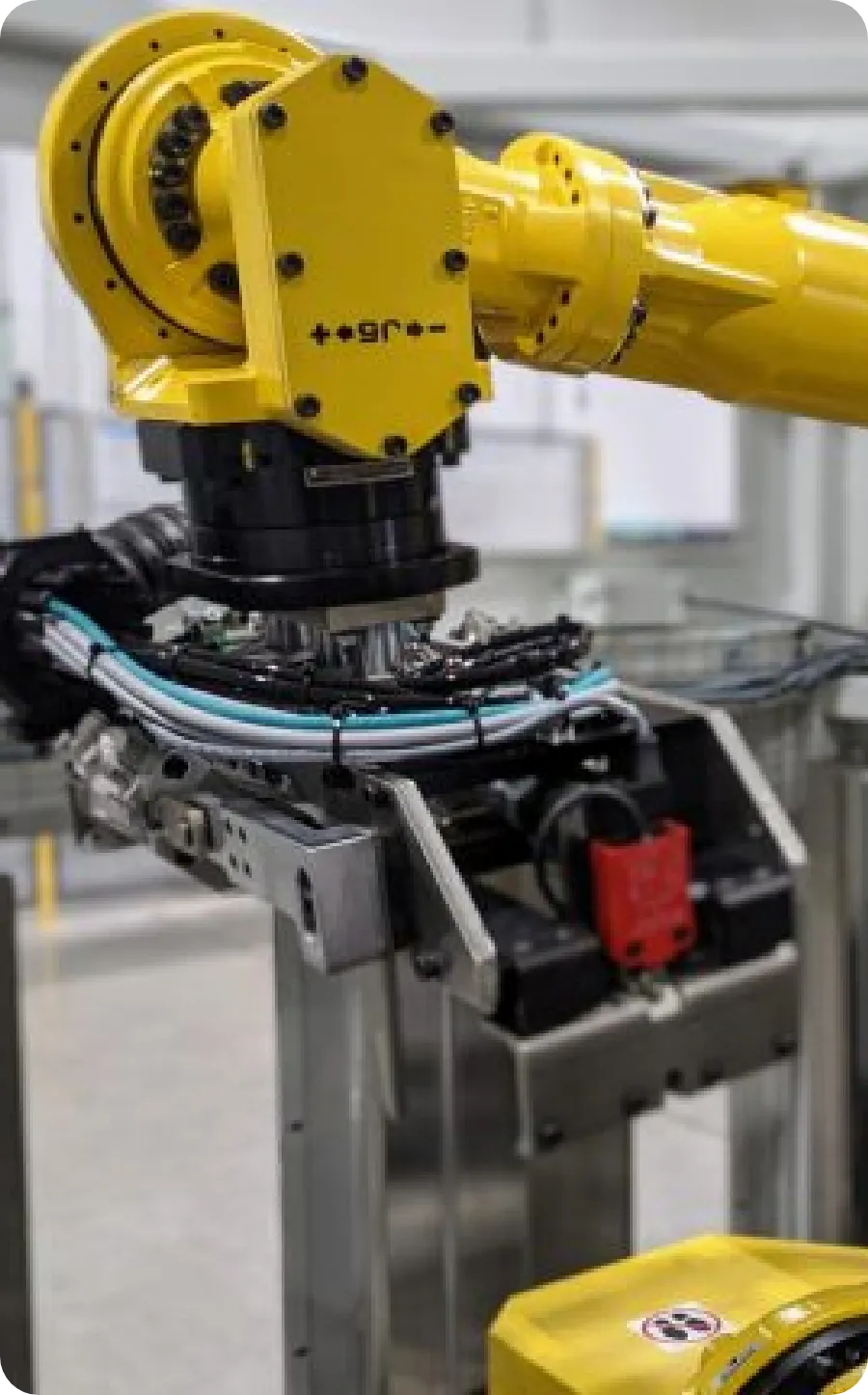

Robotic Metal Finishing

We deliver robotic deburring, edge break, chamfering, and grinding solutions to produce consistent finishes and repeatable edge conditions on aerospace components. Projects can begin in the Matrix Deburr Lab, where we classify burrs, select tools and abrasives, and validate parameters such as feed, force, and RPM to reduce risk before the full system build. Typical capabilities include:

- Robotic deburring and edge conditioning for machined and cast aerospace components

- Touch detection and force control options to maintain consistent contact and maximize tool life

- Tooling and abrasive selection matched to the material, burr type, and required finish criteria

- Integration with proven partners including PushCorp and abrasive suppliers such as 3M and Norton Abrasives

- Optional vision-based checks to verify key features and confirm the part meets requirements before leaving the cell

End of Line Automation

Matrix designs and integrates engineered end of line and pack out automation systems tailored for aerospace production environments where part protection and identification are critical. Solutions are designed to prevent damage, maintain flow, and reduce manual handling during final operations. Common elements include:

- Robotic palletizing and pack out for components or completed subassemblies with controlled placement and protection

- Automated material handling using conveyors and robotic transfer systems to streamline movement between operations and shipping

- Integrated stretch wrapping and labeling to ensure finished parts are protected for transit and easily identified downstream

Inspection & Traceability

For programs that require verification and robust traceability processes, Matrix integrates inspection and label data capture into robotic cells and end of line systems. This ensures only conforming parts move downstream and that process history is available for audits. Options include:

- Vision systems for tolerance measurement, feature presence and position checks, and label or mark verification

- Integration of industry leading vision system technology from providers such as Keyence and Cognex

- Data logging to MES and ERP systems for historical reference, quality tracking, and audit ready traceability

Business Problems We Solve for Aerospace Customers

Aerospace manufacturers often face tight tolerances, strict finishing expectations, and documentation requirements while operating under schedule pressure. Matrix helps address:

- Maintaining tight tolerances and consistent finishing quality across repeatable part families

- Reducing ergonomic strain and labor dependency for machine tending, deburring, finishing, and pack-out tasks

- Preventing process variation that leads to scrap, rework, or missed delivery schedules

- De-risking program launches by validating automation processes before full-scale integration

- Streamlining the movement of parts between machining, finishing, and shipping operations

- Integrating robotic cells with existing machine tools, MES and ERP platforms, and quality systems

- Achieving predictable throughput and repeatable processes without compromising part protection and traceability expectations

Why Aerospace Teams Choose Matrix

- Deep expertise integrating robotic systems for precision-machined aerospace parts and castings

- Validation-first approach that de-risks automation through Deburr Lab testing and system simulation

- Proven experience interfacing with a wide range of CNC machines and plant-floor technologies to accelerate launches

- Strong focus on repeatable quality and part protection across machine tending, finishing, and pack-out operations

- Established supplier base with leading tooling, force control, and media suppliers including PushCorp, 3M, and Norton Abrasives

- Commitment to ergonomic improvement and labor risk reduction while maintaining aerospace quality standards

- Scalable automation designs tailored for repeatable part families and program growth

Matrix’s aerospace solutions are built for production environments where documentation, consistency, and controlled handling are non-negotiable. By validating processes upfront and engineering cells that integrate cleanly with your machining and quality systems, we help you improve throughput and repeatability while meeting demanding aerospace requirements.

Free Evaluation

Free Automation Evaluation Process

Have you ever thought about automating but weren’t sure where to start?

Contact us to go through our completely free Automation Evaluation Process.

By the end of this proven process, you will have a better understanding of how and where automation could fit into your current manufacturing operations.

Contact us to start your free Automotive Evaluation Process!

Customer Stories

Better Service Starts Here

As a Level 4 Fanuc Servicing Integrator, Matrix has the ability to work on any Fanuc robot system for emergency service, spare parts, or reprogramming needs.